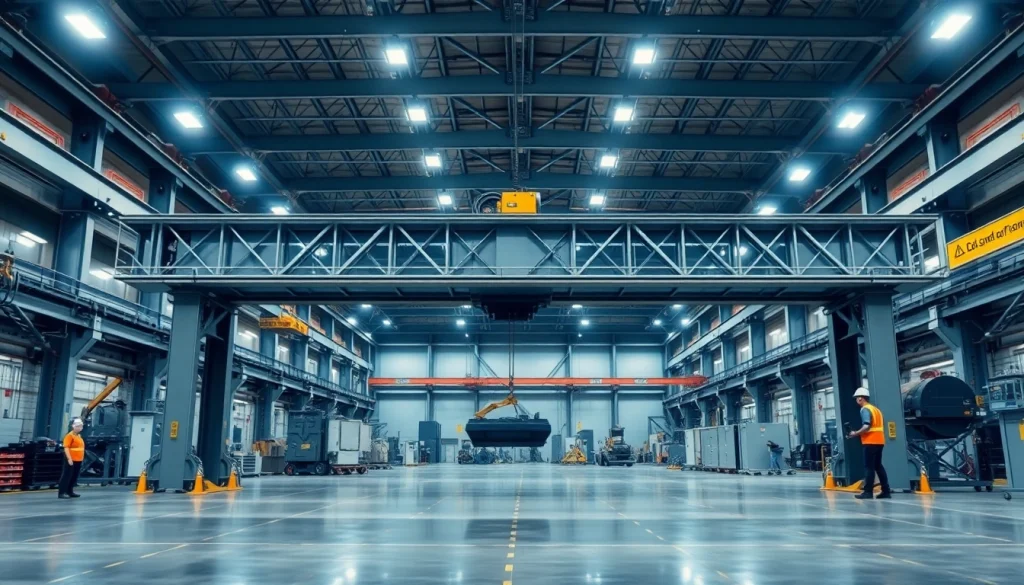

Understanding the Double Girder Bridge Crane

The double girder bridge crane is a vital piece of equipment in the industrial sector, designed for heavy lifting and superior operational efficiency. Unlike its single girder counterparts, the double girder design features two parallel girders, which significantly enhances load capacity and stability. This article explores the operational mechanics of double girder cranes, their components, and how they compare to single girder cranes, ultimately guiding you towards making an informed selection for your industrial needs.

What is a Double Girder Bridge Crane?

A double girder bridge crane consists of two main girders that run parallel to each other, supported by end trucks that enable horizontal movement. This design allows for a hoist system positioned between the girders, which can effectively lift heavy loads. It is primarily used in factories, warehouses, and heavy equipment yards where precise handling of materials is crucial. The stability and strength of double girder cranes make them an ideal choice for operations requiring lifting capabilities over 10 tons and larger spans between 60 to 100 feet.

Components and Functionality of Double Girder Cranes

The primary components of a double girder bridge crane include:

- Main Girders: These two structural components are responsible for supporting the load and are integral to the crane’s framework.

- Hoist Mechanism: The hoist travels on the lower flanges of the girders, enabling vertical lifting of materials.

- End Trucks: Positioned at either end of the girders, these support the crane’s movement along the runway.

- Control System: Allows operators to maneuver the crane with precision, enhancing operational safety and efficiency.

Each component works together to ensure smooth operation, facilitating the handling of heavy loads without compromising safety.

Comparison with Single Girder Cranes

When comparing double girder cranes with single girder cranes, several key differences arise:

- Load Capacity: Double girder cranes can handle heavier loads, making them suitable for industrial applications that require lifting loads exceeding 10 tons.

- Span Limitations: The span of double girder cranes is more extensive than that of single girder cranes, allowing for greater flexibility in layout and design.

- Stability and Durability: The design of double girder cranes contributes to improved stability when lifting heavy materials, reducing sway and increasing operational safety.

Overall, while single girder cranes are more cost-effective for lighter applications, double girder cranes excel in heavy-duty scenarios.

Choosing the Right Double Girder Bridge Crane

Choosing the right double girder bridge crane involves careful assessment of various factors, ensuring that you select a crane suited to your specific operational needs.

Capacity and Span Considerations

When determining which double girder crane to deploy, consider both the weight capacity and span requirements of your operations. Double girder cranes are often available in capacities ranging from 10 tons to over 250 tons. Additionally, spans can vary significantly based on the operational environment and requirements:

- Weight Capacity: Assess the maximum load that will be handled and select a crane that provides an ample margin for safety.

- Span Length: Consider the width of your workshop or facility, as this will dictate the span of the crane you need.

Understanding Your Operational Needs

Every operation is unique, and understanding your specific requirements is key to choosing the right double girder crane. Consider the following aspects:

- Frequency of Use: High-frequency operations may require a more robust crane design to endure prolonged usage.

- Environmental Conditions: Assess whether the crane will be used indoors, outdoors, or in extreme conditions, which may dictate additional features for protection.

- Material Types: Different materials have varying handling characteristics, which can influence the design and capabilities of the crane.

Evaluating Design Options for Efficiency

When selecting a double girder crane, evaluate different design options to enhance efficiency:

- Control Systems: Advanced control systems enable more precise movements, reducing handling times and increasing productivity.

- Drive Systems: Choose between electric or hydraulic drive systems based on the specific needs of your operation.

- Safety Features: Ensure the crane is equipped with necessary safety features, such as emergency stops, overload protection, and anti-collision systems.

Installation and Maintenance Best Practices

Proper installation and maintenance of your double girder crane are vital for ensuring safety and longevity.

Guidelines for Safe Installation of Double Girder Cranes

Installation guidelines for double girder cranes should adhere to safety regulations and best practices:

- Site Preparation: Ensure that the installation site is structurally sound and prepared for the load distribution of the crane.

- Professional Installation: Engage certified professionals for installation to ensure compliance with industry standards.

- Testing and Commissioning: Conduct rigorous testing post-installation to confirm that all systems are functioning correctly.

Regular Maintenance Tips for Longevity

Routine maintenance is essential to extend the lifespan of your double girder crane:

- Daily Inspections: Conduct daily inspections of critical components, including hoists and control systems.

- Periodic Maintenance Checks: Schedule regular maintenance checks by trained professionals to identify potential issues early.

- Lubrication: Regularly lubricate moving parts to reduce wear and tear.

Common Issues and Troubleshooting Techniques

Understanding common issues and their troubleshooting methods can save time and prevent safety hazards:

- Hoist Malfunctions: If hoists fail, check for electrical faults, load restrictions, or mechanical failures.

- Uneven Movement: This may signify alignment issues; regular checks and adjustments can help maintain proper function.

- Control System Failures: Regularly test control systems; replace any faulty components promptly.

Performance Metrics and Effectiveness

Measuring performance metrics of your double girder bridge crane helps assess its effectiveness and operational efficiency.

Measuring Crane Performance and Reliability

Key metrics to consider when evaluating crane performance include:

- Load Handling Efficiency: Track how well the crane performs under various load conditions.

- Downtime: Minimize downtime for maintenance or repairs to improve overall productivity.

- Operational Safety: Regularly review safety incidents to identify areas for improvement.

Success Stories: Case Studies of Implementation

Reviewing successful case studies can provide valuable insights into the effective deployment of double girder cranes:

- Manufacturing Plant: A major manufacturing plant implemented double girder cranes to streamline material handling, resulting in a 30% increase in production efficiency.

- Construction Sites: Construction companies using double girder cranes reported improved safety and reduced accidents related to material handling.

How to Optimize Operations for Maximum Efficiency

To optimize operations, consider these strategies:

- Training: Provide operators with thorough training to maximize their understanding of equipment handling.

- Technology Integration: Utilize technology solutions, such as load monitoring systems, to optimize crane use and performance.

- Regular Reviews: Conduct frequent assessments of performance metrics and operations to identify improvement areas.

Future Trends in Double Girder Bridge Cranes

The landscape of industrial lifting is continually evolving, and double girder bridge cranes are no exception. Here’s a look at future trends in the industry.

Emerging Technologies Shaping the Industry by 2025

As technology advances, the following innovations are expected to shape the future of double girder cranes:

- Automation: Increased automation within crane systems is expected, improving operational efficiency and safety.

- IOT Integration: Sensors and connected devices will enable real-time monitoring and predictive maintenance.

- Enhanced Materials: Developments in lightweight but strong materials will result in stronger and lighter crane designs.

Predictions for Market Growth and Adoption Rates

Market analysts predict significant growth in the double girder crane market as industries continue to prioritize efficiency and safety. Advances in technology, coupled with an increasing focus on sustainable practices, will likely drive adoption rates upward.

Sustainable Practices and Innovations in Crane Design

Environmental concerns are prompting the industry to adopt sustainable practices. Innovations may include:

- Energy-Efficient Designs: Developing cranes that consume less power and function more efficiently.

- Recyclable Materials: An emphasis on using recyclable materials in crane construction to minimize waste.

- Green Certifications: Companies may seek cranes that meet green certifications for environmentally friendly practices.